Last week we continued our article series on the challenges of keeping IT equipment cool in high density environments. This week, we outline some potential containment solutions.

Get the full report.

Cold Aisle vs Hot Aisle

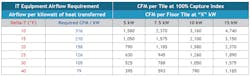

One of the most asked questions and “hotly” debated answers to the Cold Aisle vs Hot Aisle containment which is better question are: Cold, Hot or the classic “it depends.” Here are some of the issues which relate to the type of facility design and other related factors. Note that all statements below are based on the following assumptions: ITE delta-T range is 20°F to 25°F (see Table 2), there is sufficient underfloor pressure to produce the desired airflow (CFM) for the type of perforated floor tile or grate (adjusted for the capture index), the temperature of the supply air from the floor tile or grill is within ASHRAE recommended 64.4 to 80.6°F, and that there is good rack hygiene in place.

Table 2 – ITE Airflow Requirement vs Delta and corresponding CFM per supply floor tile

*Note: For purposes of these examples, we have simplified the issues related regarding latent vs. sensible cooling loads (dry-bulb vs. wet-bulb temperatures). The airflow table is based on dry-bulb temperatures.

No Containment

Setting aside the potential fan energy efficiency saving, generally speaking it is possible to maintain sufficient airflow and ITE intake temperatures at 5-6-kW per rack without any containment. It requires more fan energy and becomes much more difficult to go much higher power levels without some level of containment.

Cold Aisle Containment

Partial Containment

END OF AISLE DOORS

The first stage is end of aisle doors, which creates a “bathtub” of cold air. This will usually help increase and maximize the available airflow to ITE installed in lower portion of the racks. Power per cabinet 5-8 kW.

COLD AISLE WITH COLLAR WITH OPEN TOP

This adds an 18-36″ containment collar around the cold aisle in addition to the end of aisle doors, which prevents hot air from being drawn into ITE located closer to the top of the rack. This allows more ITE to be stacked higher raising the effective power range to 10-12 kW.

Generally speaking, both partial containment options listed above will avoid issues with local fire codes.

Complete Cold Aisle Containment

This option offers the best level of airflow concentration and allows much higher power levels, assuming there is sufficient cooling airflow available. This can support 20-25 kW with a 2 tile cold aisle, however by going to a 3 tile cold aisle it is possible to support 30 kW or more per cabinet.

One of the concerns about adding complete containment is local fire codes, which may require extending fire suppression discharge nozzles into the contained aisle. However, there are several solutions that can avoid this. Most of the solutions are based on some methodology to have the roof of the contained area drop down, or open up, once a specific temperature is reached, or if smoke or fire detection system detects a pre-action or other trigger conditions.

It should be noted that any of these options must be approved by the local fire codes and that some Fire Marshalls may consider anything drop-down a potential hazard to first responders. A containment roof system which can be tied into existing fire system and automatically open without dropping anything down may alleviate the need for costly sprinkler system modifications.

COLD AISLE WIDTH

The above is based on a 2 tile cold aisle. One of the benefits to consider is increasing the cold aisle width to 3 tiles. This requires less under floor pressure per tile, for the same total required CFM. This reduced pressure, in turn decreases floor leakage, as well as the velocity related Venture effect issues as discussed above. Collective result reduced cool unit fan energy, improving the facility PUE.

As a rule of thumb, a one degree increase of chiller supply temperature results in approximately a two percent energy savings, depending on age and type of chiller.

For raised floors facilities without a plenum ceiling, cold aisle containment is usually the easiest to install and offers the most flexibility. While the cabinet power density ranges were based on an ITE D-T of 20-25°F, with higher density ITE operate a higher D-T (30-40°F) to allow for higher power densities at the lower facilities with lower available airflow. However, it is important to understand the rest of the space effectively becomes at or near the ITE exhaust temperature. If the average cold aisle supply temperatures are 70-75°F, the resulting hot aisles are 90-100°F or even beyond 110°F with high Delta-T IT equipment.

Another factor to consider, is the type of cooling systems; for chilled water with CRAHs higher return temperatures (90°F or higher) are usually no problem. In fact they increase the net cooling capacity of the CRAH and also allow the chilled water temperature to increase saving chiller energy. As a rule of thumb, a one degree increase of chiller supply temperature results in approximately a two percent energy savings, depending on age and type of chiller. Of course several caveats apply; the range of improvement is specific to the chiller specifications such as; the maximum supply, return and chiller D-T.

For DX CRACs, the maximum return temperature is typically more limited (85-90°F), especially for older units. Some newer CRACs have somewhat higher air return limits (90-100°F), however, generally the benefits in performance and energy saving increases are not as great as chilled water based systems.

Hot Aisle Containment

Unlike cold aisles, which typically require raised floors (or overhead supply ducts), hot aisle containment can be used with or without a raised floor. The three most common configurations are raised floor and slab floor, either with or without a plenum ceiling.

Partial Hot Aisle Containment

End of aisle doors and an 18-36″ containment collar around the hot aisle, in addition to the end of aisle doors, which also prevents hot air from being drawn back into the ITE intake closer to the top of the rack in the cold aisle. This allows more ITE to be stacked higher, raising the effective power range to 10-12 kW.

Plenum ceilings

A plenum ceiling that is fully coupled to the cooling units return (typically by means of ducted collar to the ceiling), improves partial containment performance, assuming the ceiling return grills are properly aligned over the hot aisles. This also improves uncontained hot aisle layouts. A plenum ceiling is essential for full hot aisle containment.

Complete Hot Aisle Containment

This option offers the best level of return airflow control and allows much higher power levels, assuming there is sufficient cooling capacity available. Similar to the CAC this can support 20-25 kW with a 2 tile cold aisle, however by going to a 3 tile cold aisle is possible to go 30 kW or more per cabinet.

One of the benefits of “flooded room” systems is avoidance of trying to match various types of floor tiles to the CFM requirements for different power densities.

It is also the first choice for fan-wall cooling units, and other “flooded room” designs, such as rooftop cooling units with overhead ducts, with or without raised floors.

One of the benefits of “flooded room” systems is avoidance of trying to match various types of floor tiles to the CFM requirements for different power densities. When implemented correctly it also lessens the impact of varying underfloor plenum pressures.

Download the entire paper, “High Density IT Cooling – Breaking the Thermal Boundaries“ courtesy of TechnoGuard, to learn more. In our next article, we’ll discuss the importance of rack hygiene and the energy efficiency cost of airflow leakage. Catch up on the previous articles here and here.