From Waste to Well-Placed: Data Center Heat Recovery

The Challenge

Data centers have transformed the digital world, processing massive amounts of information at high speeds. Nearly 100% of electrical energy consumed in the process is converted to heat, which must be removed to prevent IT equipment from overheating.

Given the energy consumption of data centers, this heat is significant. The International Energy Agency reported that data centers used 1.5% of the world's electricity in 2024, with expectations that this figure will more than double by 2030. Traditionally, this heat is rejected to the atmosphere. Fortunately, we can recover this heat, turning it from waste to resource.

Heat Recovery Fundamentals

Heat recovery isn't new. Water-cooled chillers have been used for 80+ years to recover heat. Applying this to data centers isn't novel, either. For instance, a 5MW data center in Sweden, designed in 2017, provided heat to 10,000+ apartment buildings through Stockholm’s Open District Heating. In 2019, a German data center's waste heat was used to heat commercial office spaces and 400 apartment buildings while maintaining a Power Usage Effectiveness (PUE) below 1.34. There are significant opportunities around the world to recover heat and apply it to commercial comfort and district heating, as well as manufacturing, process, and industrial heat applications.

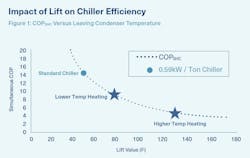

Recovering heat increases chiller efficiency and reduces total energy consumption and emissions by replacing less efficient heating equipment. Chiller efficiency is measured by either kW/ton or Coefficient of Performance (COP), the useful work output divided by electrical input. For chillers that simultaneously provide cooling and heat recovery, the COPSHC (Simultaneous Heating and Cooling) is used. COPSHC is more than twice the cooling-only COP, outperforming natural gas boilers or electric heat, which have COPs ≤ 1.

Best Practices for Data Center Heat Recovery:

- Cooling Loop Temperature: Control to the warmest fluid temperature in the cooling loop while ensuring uptime requirements.

- Positioning: Place heat recovery to access the warmest fluid from the chiller.

- Direct Use: Use warm fluid directly if low-grade or low-temperature fluid is needed.

- Booster Heat Pumps: Use booster heat pumps if higher fluid temperatures are required.

Optimizing Performance

Using warm fluid directly typically consumes less energy than raising or lowering its temperature. In some cases, such as pairing IT equipment with heat users like greenhouse farms, a heat pump may not be needed. In many scenarios, at least one heat pump stage is required to reach the desired hot water temperature.

By keeping the cooling loop at the highest possible fluid temperature and lowering the hot water temperature produced by the chiller, the lift (the difference between the supply and return temperatures) is reduced. Since the power a chiller consumes is proportional to the load times the lift, a lower lift results in a higher COPSHC.

For example, a chiller supplying chilled water to an immersion cooling station while providing hot water to a facility with heating coils designed for a 105°F supply fluid would result in significantly less lift than if the chiller were supplying chilled water to a CRAH and hot water to coils designed for 140°F supply.

Managing the Load

The turndown capability of a chiller or heat pump varies depending on the technology and sizing. Maintaining higher lift conditions reduces turndown capability, as the machine will hit operational limits at a higher part-load ratio than lower lift conditions.

The heat a water-cooled chiller can provide is limited by the heat extracted by the evaporator plus the heat of compression. If the data center cooling load is insufficient to meet the heating load, additional heat sources will be needed.

If higher temperatures are required than the data center heat recovery can reliably provide, consider using booster heat pumps. The data center chiller’s leaving condenser fluid runs through the evaporator of the booster heat pump, cooling the chiller’s condenser fluid while producing higher temperature booster condenser fluid for heat consumption.

Leveraging a Golden Opportunity

Recovering heat is a well-established way to improve efficiency and reduce emissions. Consider load ranges, daily load swings, and uptime expectations to determine the best mix of systems and required redundancy. Regardless of end use, the closer in proximity the heat source and consumer are and the more compatible the load profiles, temperature ranges, and uptime requirements, the more practical and efficient heat recovery becomes.

For more information, join us at trane.com.

About the Author

Michelle Hull

Michelle Hull serves as an Applications Engineer for Trane, specializing in hydronic systems, heat recovery, and energy modeling. In this role, Michelle supports a variety of applications, from high schools to data centers. Her background includes equipment testing and developing Trane’s building performance simulation tools.