The CoilWall and Fan CoilWall are Hot Data Center Cooling Trends

In this edition of Voices of the Industry, Kris Holla, Group Vice President & Chief Sales Officer of Nortek Data Center Cooling discusses CoilWalls and Fan CoilWalls, two new innovations in data center cooling.

Kris Holla, Group Vice President, Channel Sales for Nortek Air Solutions

The adage, “old habits are hard to break” rings true for data center operators that continue to use computer room air handlers (CRAH) for medium and large data hall cooling.

A CRAH is essentially a “box” with a large fan (or fans), a redundant fan, cooling coil and associated controls that are all standardized and pre-packaged inside a large cabinet. Thinking “outside the box” is one way data centers can create more efficiency and server space, while reducing mechanical cooling footprints and total cost of ownership for the data hall.

The CRAH is not a “bad habit.” It’s a great product and a stalwart of data hall cooling for decades. It’s still ideal for quick and easy installation in smaller applications that need simple, commodity cooling. However, amid the trend toward larger data centers, there are several alternative innovations that exceeds CRAH cooling capacity but offer up to 50% more efficiency from a smaller footprint, but with larger capacity.

A CRAH is a terminal for a separate chilled water loop that is supplied by either an indirect evaporative cooling plant such as a StatePoint, or direct evaporative cooling, or refrigerant-based chiller. The CRAH evolved from the computer room air conditioner (CRAC), which was a 1970s-era self-contained mechanical refrigeration system positioned inside data halls. CRACs are expensive to purchase, operate and maintain, plus today’s cooling technology is moving away from vapor-compression refrigerants, because of their environmental impact and liability. Now as data hall dimensions grow larger, the CRAH’s limited selection of heights, widths, lengths and large footprints limit popular design trends, such as greater efficiency, capacity and more server space. Basically, CRAHs are an “off the shelf” catalog item with little opportunity for customization.

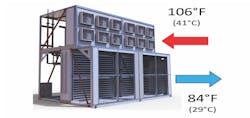

As the data center industry grew from 10MW to 100MW buildings the last five years, mechanical designers sought more cooling capacity, but with better efficiency and smaller footprints. Consequently, the CoilWall (CW) and the Fan CoilWall (FCW) are two new innovations that solve those challenges. They both accommodate the trend toward smaller footprints, modular units, more efficiency, and fast, flexible installation.

Illustration: CoilWalls and Fan CoilWall units are replacing conventional technology, such as the CRAH and CRAC units, all which can be supplied by a chilled water cooling central plant, such as a StatePoint. (Photo courtesy of Nortek Data Center Cooling).

The CW has no cabinet, therefore up to 40% more coil area is possible in the same footprint of a CRAH. That additional coil surface makes the CW three times more efficient than a CRAH. In addition, a larger coil surface area also can allow higher, more energy efficient discharge temperatures from the chilled water loop supply.

Along with large coils, electronically-commutated motor (ECM) fans and their variable speed capabilities play a significant role in the total efficiency and operational cost, especially under part load efficiencies.

In addition, a larger coil surface area also provides smaller approach temperatures and longer hours of larger economization. When combined with an indirect evaporative cooling plant, such as StatePoint technology, the results are significantly lower PUE than conventional cooling systems and CRAH units.

Illustration: A CoilWall’s fan array pulls in warm data hall air and pushes it through the cooling coil. (Photo courtesy of Nortek Data Center Cooling).

CWs are also easily customizable. It’s simply a coil with a fan array and control package. Designers can choose to build-out an insulated drywall or steel plenum around it, in which the CW becomes the wall of the data hall. If a data hall is 12-feet-high for example, manufacturers can simply create a coil to accommodate that height. Customizing a CRAH to accommodate a particular height is very expensive.

The absence of a heavy metal cabinet relates to less weight, which makes them easier to rig into place, relocate or replace.

Width doesn’t pose a problem, because CWs are modular and designed for scalability simply be tandem-connecting with quick-connect fittings.

Furthermore, maintenance accessibility is simplified, because service techs have ample space to walk between the coil and the wall for repairs or replacement.

The CW also benefits from the development of fan array technology, such as Fanwall, which supplants one large fan with multiple, smaller fan wheels mounted in parallel cubes that can be easily replaced. The array has redundancy benefits over one large fan, because fan optimization controlling automatically engages other fans in the array to maintain set point temperature in the event of a failure. Fan arrays also promote more energy efficiency, because not all fans operate 100% of the time, which can save up to 35% in energy versus single, large fans, especially when highly—efficient ECM fans are specified.

Illustration: A CoilWall with ECM fans. (Photo courtesy of Nortek Data Center Cooling).

The fan array can be mounted either on top or the side of the CW. It pulls warm air from the ceiling of the data hall. This pressurizes the plenum and pushes the air through the cooling coil.

Contrary to the CW, the FCW has more framing and substructure, but it’s also designed to use the data hall wall as the back end of its enclosure, thus saving steel and cabinetry costs. It also uses fan arrays.

Illustration: The Fan CoilWall has a substructure, but not the cabinetry of a CRAH. It’s a modular unit that gives mechanical designers data hall layout flexibility. (Photo courtesy of Nortek Data Center Cooling)

Its modular construction allows it to be shipped in pieces with easy site assembly. The modularity allows factory design flexibility for numerous site configurations, whereas the CRAH is simply a non-configurable catalog item.

Multiple FCW units can be easily connected in tandem for scalability that is only restricted by the data hall cooling space allotment. Like the CW, it has a coil surface area that can span from the floor to ceiling to increase overall efficiency. Service technicians can literally walk through connected modules for service.

The FCW is favored among some top hyperscale data centers for its flexibility for accommodating perpetually-changing data center designs in search for optimum efficiency.

Any medium to large data center operator seeking smaller cooling equipment footprints, increased efficiency, more server space and the other benefits the CW and FCW offer, should go “cold turkey” and kick the CRAH habit.

Kris Holla is Group Vice President & Chief Sales Officer, Nortek Data Center Cooling, St. Louis, Mo. Connect with Kris on LinkedIn.