How Construction Robots Are Helping GCs Meet Unprecedented Demand

If you build data centers, you are at the epicenter of a technological sea change. Driven by both AI and still-growing cloud, the pace of demand is unprecedented, as is the scale. Capacity in Tier 1 markets is constrained, so development is moving to smaller cities and rural areas, where skilled labor is even harder to come by. At the same time, hyperscalers face ever-more scrutiny about the local impact of their data centers – pressure they’re passing on to their contractors.

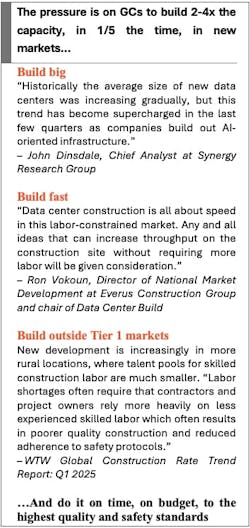

The pressure is on general contractors to build 2-4 times as much data center capacity in the next five years as in the previous 25 – in new markets, to the highest quality and safety standards. As you strategize how to achieve that, drywall might not be top of mind. But drywall is critical path for commissioning. Getting it done faster, even without large pools of skilled labor, is essential to delivering on time and on budget.

The old way of doing things won’t suffice. As Bill Kleyman, program chair for Data Center World and the author of AFCOM’s State of the Data Center Report put it, “The reality is pretty straightforward: we can’t build data centers the same way we used to. The good news is that there are a lot of innovative leaders.”

2: Source: IDC, 3: Source: JLL, 4: Source: McKinsey, 5: Source: Lawrence Berkeley National Laboratory and CBRE

The key: Construction robots.

WTW put it well in the Q1 2025 Global Construction Rate Trend Report: “The future of construction is being shaped by the integration of AI and robotics…the industry [is] increasingly adopt[ing] these innovations to remain competitive and meet project deadlines.” Drywall robots, in particular, enable general contractors to do height work faster, get new workers trained quickly, and ensure the highest levels of quality and safety.

Do more, faster

One of the particular challenges in hyperscale data center construction is the sheer size of the builds. Drywall production rates with traditional methods are typically 50% lower above 10 feet. With an integrated 20-foot lift, the Canvas robot is 100% productive at any height. In addition, with a robot’s ability to auto position, one worker can operate multiple machines.

Of course, these productivity advantages depend on the ease and speed with which the robots can be set up and the level of reliability at which they operate. Canvas robots are designed to set up in minutes on any site, no plans or mapping needed. Powerful AI models automatically split the wall into workspace and target key features. Users can quickly set the target finish, review the plan, and move on to parallel tasks.

Furthermore, because robots are a digitally native tool and capture accurate data about the work being done, they offer valuable data insights. Unprecedented visibility into workflows enables project teams to identify bottlenecks and drive improved efficiency.

Deliver even in markets where skilled labor is constrained

Data center development is now more likely to be outside Tier 1 markets, in smaller cities and rural areas where talent pools for skilled construction labor are much smaller. Adding to the hiring challenge are hyperscalers’ increasingly strict drug testing requirements. But with robots that are easy to set up and operate, you can get new drywall workers trained up in as little as a week. Integrating robots into your workflow has the added benefit of expanding workers’ skill sets; by handling repetitive, high-precision tasks, robots free up workers for more complex jobs.

Maintain rigorous standards of quality and safety

Meeting building demands means bringing new apprentices up to speed quickly. Relying on less-experienced and less-skilled finishers risks mistakes and injuries, which may impede on-time delivery. A robot produces high quality output consistently, regardless of the operator’s skill level. When the robot detects and automatically calibrates to incoming conditions, compensating for any conditions that are out of spec, it ensures accuracy and maximum uptime – critical when timelines are tight and tolerances are shrinking.

Safety has always been paramount, of course. Because hyperscalers face increasingly tough scrutiny of their developments, a perfect safety record is now a likely requirement for general contractors. Falls are the leading cause of construction injuries, so drywall robots with a 20+ foot reach improve jobsite safety. They also prevent chronic injuries associated with repetitive motion (25% of workers have work-related Musculo-skeletal disorders) and prolong workers’ careers.

Now’s the time to integrate drywall robots

The data center construction industry is at an inflection point. Forward-thinking GCs are, as WTW explained, leveraging robots to remain competitive and meet project deadlines – especially for critical path work like drywall. It’s a competitive advantage, and now is the time to harness it.

While drywall robots can be integrated quickly and easily, becoming really good with robots as an organization is a skill that has to be developed. The contractors doing it now are already reaping competitive advantages in speed, scale, quality and safety; they’re also getting ahead of competitors by building a culture designed to reap the rewards of technological advancements in robotics and AI – today’s, and tomorrow’s.

About the Author

Kevin Albert

Kevin Albert is co-founder and CEO of Canvas, a construction technology company revolutionizing productivity by building an entirely new class of robotic machinery. With the only drywall robot that does a Level 4 finish, Canvas is enabling data center GCs to meet unprecedented demand.