Solving AI Data Center Challenges with Agile Grid Forming BESS

As AI workloads scale, data centers are facing new operational challenges that can cause construction and interconnection delays. Two key impediments have arisen: 1) extreme load variability of GPUs, and 2) grid operators’ need for large loads to remain connected during grid disturbances. Addressing these issues is beyond the ability of both UPS based systems, as well as traditional grid-forming Battery Energy Storage Systems (BESS). With these new challenges, obtaining grid interconnections and protecting on-site generation from load fluctuations are becoming the critical challenges to the deployment of data centers. As the largest US manufacturer of energy storage inverters for utility-scale projects, EPC Power Corp. (EPC Power) presents a clean solution to both challenges in the form of its Agile Grid-Forming technology.

Load Variability Smoothing

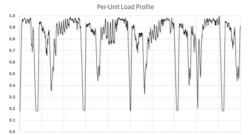

AI data centers, particularly those running GPU-intensive workloads, exhibit highly variable power profiles. These rapid fluctuations cause power quality issues, and even more importantly, damage to generation assets through torque pulsations.

To smooth this load, a few locations stand out: near the load (at the rack), at the UPS, or at the substation/connection to the grid. Rack-based solutions seem to be a great, albeit rather expensive, place to start. Most rack solutions are based on supercapacitors or other short duration energy storage technology to take out the most severe ramps. If this is the only solution, more energy storage (i.e. longer duration) is still needed elsewhere to bring ramp rates low enough to comply with turbine, reciprocating engines, or utility rate limitations. The end result is an expensive and complex solution, which consumes data center whitespace.

Smoothing at the UPS gets the equipment somewhat out of the data center and has a little longer storage duration (minutes), but these systems weren’t originally designed to handle the severe ramp of the load, nor are they as robust as even standard BESS technology when it comes to maintaining the load on the utility or prime mover during a disturbance. Still, a few questions remain: Are minutes of energy storage enough? Can the UPS survive long-term with severe thermal cycling? Is the true purpose of the UPS still appropriate for this application?

When we look at smoothing the load at the utility connection, this location allows the use of BESS for other grid benefits outside of the base load smoothing use case (arbitrage, demand management, ancillary services, etc.). The first approach we’ll evaluate is a grid-following BESS solution. In this type of system, the command setpoint for power is decided by a higher-level controller (Power Plant Controller, or PPC) which inserts a delay of tens to hundreds of milliseconds until the signal reaches the inverter. This delay severely limits the ability of the system to null out load fluctuations.

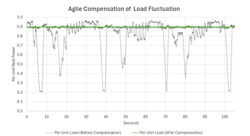

The next best solution is a more advanced “grid-forming” BESS solution. These systems are better at reacting on their own in a few milliseconds to frequency and voltage deviations caused by the load. However, the system response greatly depends on whether the BESS is grid-connected, the strength of the grid, on-site generation, etc. Ultimately, a grid-forming BESS can only compensate 40%-60% of the load fluctuations. While this can reduce the issue, it still doesn’t solve the issue.

The next evolution of a grid-forming solution is EPC Power’s Agile Grid Forming BESS. Improving upon grid-forming BESS, an Agile Grid Forming BESS can cleanly compensate nearly 100% of the load step, far-surpassing the performance of advanced grid-forming solutions. This performance can be had both in strong utility-connected systems such as PJM, or weak islanded systems with on-site gas turbines.

Risk of Load Shedding at Unprecedented Scale

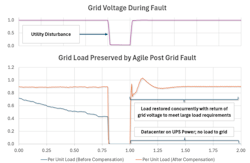

During undervoltage events or other grid disturbances, low-voltage UPS typically take the load off the grid and onto backup power. With the expansion of data centers in nearly every market in the gigawatt scale, this increases the risks posed to utilities. Having a large 1GW+ load disappear from their system during these transients is nearly as bad as a 1GW+ generation facility tripping and causing unforeseen risk to the bulk electric system.

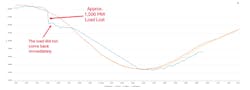

These are not theoretical concerns. The North American Electric Reliability Corporation (NERC) has highlighted the risks of simultaneous voltage-sensitive load reductions in recent reports, with a real-world example of 1,500MW of data center load lost from the grid for hours, as shown in the following plot.

ERCOT has a Large Load Working Group that is also trying to solve these problems, as well as many other Independent System Operators (ISOs). One thing is clear: Interconnection rules are changing for these large digital loads. Said in another way: project delays and cancellations until this is solved.

The challenge will be the balance between keeping the same level of reliability that data centers expect, while also remaining connected to the utility during grid disturbances. With an Agile Grid Forming BESS co-located with the data center, the data center can operate as designed – taking load offline temporarily. Once the fault clears, the BESS will automatically mimic the last operational setpoint of the load until the UPSs reconnect to the grid, maintaining load continuity in the eyes of the utility. Additionally, in the event of a grid disturbance, the native response of the Agile Grid Forming BESS will naturally minimize the voltage drop experienced within the data center, further enhancing overall system stability.

A Future-Ready Approach to AI Infrastructure

As AI continues to reshape the data center landscape, power systems must evolve to meet new demands. EPC Power’s Agile Grid Forming solution offers a future-ready approach, combining fast response, grid support, and flexible integration to ensure reliability in the face of extreme variability. EPC’s solution integrates seamlessly with existing infrastructure, offering retrofit and greenfield opportunities for developers.

About the Author

Devin Dilley

Devin Dilley is co-founder, President, and Chief Product Officer of EPC Power. He has over 20 years of experience in power electronics and holds BSEE and BSME degrees from Clarkson University.

EPC Power designs and manufactures advanced inverters that enable reliable, efficient, and scalable power for data centers. With more than 15 years of U.S.-based manufacturing, EPC Power delivers modular solutions engineered to meet the high-performance demands of large-scale data center infrastructure.