Bringing the Physical Fiber Layer into the 21st Century

Bob Shine, VP of Marketing and Product Management at Telescent, highlights how data centers are working to respond to today’s network and data traffic needs. Explore the potential of the physical fiber layer.

Bob Shine, VP of Marketing and Product Management, Telescent

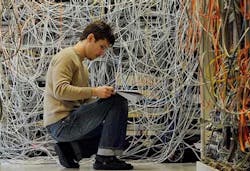

From the early days of the Internet to today, data traffic has grown exponentially. As a statistic to demonstrate just how much data is being generated and consumed, 90% of the data that exists today has been generated in the last 2 years (OCP Plenary, May 2020). Networks have responded to this exponential growth by improvements in hardware as well as network architecture designs. Backbone transmission speeds have increased orders of magnitude and is evolving to speeds of 400 Gbit/s. Network architectures have also evolved from static and decentralized networks to using Software Defined Networking (SDN) that allows flexibility and easier troubleshooting. While almost every network component has evolved from the early Internet days, there is one function that is still done the same way it has been done for 30 years – the manual patch panel for physical fiber cross connects.

To cite a recent article from Data Center Frontiers: “The COVID-19 pandemic will drive innovation in data center operations, forcing companies to embrace automation to manage some duties that currently rely on close human interaction. Software and robotics will play larger roles in aspects of operations, and contactless, “lights out” strategies will gain new urgency in maintaining existing mission-critical facilities and building new ones.” (https://datacenterfrontier.com/pandemic-prompts-new-urgency-for-ai-automation-in-data-centers/ ) It is time to bring the fiber cross connect into the 21st century by incorporating robotics and software control.

The need for software control at the network level was driven by trends such as changing traffic patterns, the rise of cloud services and Big Data. New applications drove new traffic patterns that were more machine-to-machine (“east-to-west” traffic) compared to the older network usage that was more client-to-server (“north-south”). The rise of cloud services and mobile devices has increased the diversity of access to applications and data – consumers want access to their data from home, office and on the road. And Big Data technologies such as machine learning or natural language processing have created huge datasets with increasing and variable demand on compute power and storage. SDN aimed to address these challenges by introducing a protocol that was directly programmable, agile, centrally managed and programmatically configured. While SDN can be applied to the transport, switching and routing level of the network, the underlying physical network has remained static.

Some attempts have been made to allow software control of the cross connects through virtualization. This function is available through products such as cloud exchanges or multi-cloud connectivity where with one physical cross connect to the exchange, an enterprise can access multiple cloud vendors or service providers through the exchange’s routers and switches. However, this virtualization still depends on having the underlying physical connection to the desired network or cloud provider which is still provisioned manually.

Another benefit of automation is to reduce manpower requirements and improve quality. A recent article by the Uptime Institute tracking outages and slowdowns caused by the COVID-19 pandemic stated that “some recent data center outages that Uptime Institute has tracked were clearly the result of operator or management error — but this is a usual occurrence.” In a separate article about the major concerns of data center operators, 60% of data center owners reported difficulty finding or retaining skilled staff, with research showing that insufficient staffing can be associated with increased levels of failures and incidents. Implementation of automated cross connects can reduce both operator error and the need for additional staff, solving each of the problems listed above.

So with the many benefits of automating the fiber cross connect, what has caused the delay in implementing a new solution? Two of the main concerns for implementing any new technology in data centers are reliability and scalability. For new technology to be adapted, it must meet the current performance standards while offering key improvements. However, early designs for automated cross connects used MEMS technology, which had much higher loss than a simple fiber patch panel and all the connections would fail if the MEMS switch lost power. Clearly this is unacceptable in a data center where uptime is critical.

Figure 2. Telescent NTM in a Data Center (Photo: Telescent)

Scalability is another crucial feature for implementation of an automated cross connect system. A typical Meet-Me-Room (MMR) in a multi-tenant data center or colocation facility can have a thousand or more cross connects. Most data center locations have grown into campus environments with 10 or more buildings with a high level of cross connections across the campus. A successful automated cross connect system must be capable of scaling to 10,000 or more cross connections with a single orchestrator system controlling the automated cross connects spread across the campus. If the automated cross connect system only has a few hundred connections, it is either very difficult or prohibitively expensive to scale across a campus-wide environment while providing any-to-any connectivity.

New automated systems such as the Telescent G4 Network Topology Manager (NTM) now allow software control of the physical layer with dynamic control of cross connects while offering remote diagnostic capability such as power monitoring or OTDR functionality. The Telescent NTM uses a robot to route a fiber to any of the ports to offer any-to-any connectivity of the 1,008 ports in each system. The NTM can be initially configured with fewer than the full number of ports and upgraded in a pay-as-you-grow manner. Once made, the connections are equivalent to existing fiber patch panel connections with low loss and are fully latched, allowing traffic to continue uninterrupted as the system is upgraded. The Telescent NTM has passed NEBS Level 3 reliability testing as well as multiple vendor specific qualification tests which have demonstrated a >10 year lifetime. Multiple NTMs systems can be managed through software control offering scaling to 10,000 cross-connects and beyond with machine accurate record keeping and limiting stranded capacity.

To close with another quote from the first article referenced earlier: “If ever there was a time for data center owner-operators and their customers to embrace automation and remote management and monitoring of their infrastructure, that time is now,” said Phillip Marangella of EdgeConneX. With the Telescent NTM, the physical fiber cross connect can finally be brought into the 21st century.

Bob Shine is VP of Marketing and Product Management at Telescent.